[processing]

// Global variables

float radius = 50.0;

int X, Y;

int nX, nY;

int delay = 16;

void setup(){

size( 600, 320 );

strokeWeight( 3 );

frameRate( 15 );

X = width / 2;

Y = height / 2;

nX = X;

nY = Y;

gear = loadImage("/sites/default/files/styles/large/public/gear2.png");

belt = loadImage("/sites/default/files/styles/large/public/belt.png");

}

//Variables

float angle;

float cosine;

PImage gear;

PImage belt;

void draw(){

background(102);

radius = radius + sin( frameCount / 4 );

// Track circle to new destination

X+=(nX-X)/delay;

Y+=(nY-Y)/delay;

// Fill canvas grey

background( 80 );

// Set fill-color to blue

fill( 0, 121, 184 );

// Set stroke-color white

stroke(255);

image(belt, 130-gear.width/2, 160-gear.height/2);

angle = angle + 0.05;

translate(130,160);

pushMatrix();

rotate(angle);

image(gear, -gear.width/2, -gear.height/2);

popMatrix();

translate(369,0);

pushMatrix();

rotate(angle);

image(gear, -gear.width/2, -gear.height/2);

popMatrix();

}

[/processing]

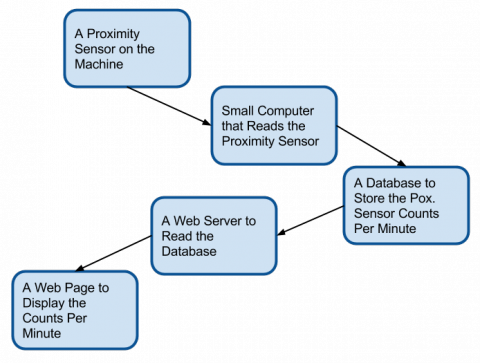

- Basic parts of a production rate data collection system

- Sensor counting finished products

- Computer reading the sensor and calculating products per minute

- Database for the computer to store the products per minute values

- Intranet server for reading the database and serving applet pages

- Applet for displaying the products per minute in a browser

After these basic parts are in place more complex processes such as analytics, feedback controls, and inventory tracking can be added.